Why the need to powerflush?

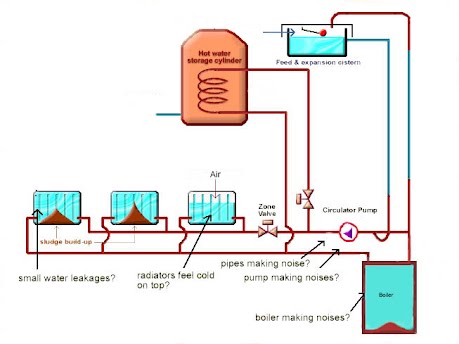

Every so often central heating systems and boilers can suffer from blockages, corrosion, leaks, loss of performance, noises, airlocks, poor efficiency and many more symptoms. The cause of these many problems can sometimes be due to the chemistry of the water running through the system. But what happens and why?

Corrosion Takes Hold

The materials we use in central heating are brass, copper, iron and steel, lead, aluminium, plastics and rubbers. The common factor we have amongst these materials is the water running through the system. What we can sometimes get if we aren't careful is corrosion!

Catalytic Corrosion

When we install heating pipework we use a flux to clean the pipes and fittings, if we don't remove this flux, it can turn the water in the system slightly acidic, then the materials in your system start reacting with each other in a undesirable way. As a by-product of this chemical reaction, we get black iron oxide and hydrogen. Thats black gooey water and lots of gas inside your system. Because the gooey water has slightly abrasive qualities, it acts like liquid sandpaper, rubbing your radiators thin from the inside, which can lead to pinholes and radiators splitting. And because you are getting lots of air in your radiators, things don't work as well as they should do. It also gets into boiler and system components causing endless problems.

Symptoms = very black water in system, component failure, leaks, lots of air in radiators, noisy system,

Solution = powerflush and system protection filter, finished off with inhibitor

Oxidic Corrosion

There is another form of corrosion called oxidic corrosion. This is whereby air is getting into the system somehow, and causing your system to corrode from the inside. The main causes of this being lack of corrosion inhibitor in the system, or problems with pipework design around the pump.

When we fill our heating system up, we are put fresh oxygenated water into a system full of metal radiators. Taking radiators off to decorate and then refilling the system is a major cause of future problems, as the corrosion inhibitor is diluted, so it is important to get your inhibitor levels checked. For a system that by design heats up and cools down, rust will take hold within a short space of time. Inevitably we are going to get problems unless we do something to neutralise this reaction. So, we use something called Inhibitor, sometimes known by the brand name of "fernox". This has special chemicals inside the stop the oxygen causing problems with the water and metal. But the design of the system can also cause a problem in introducing air into the system

How can pipework cause a problem?

If you have a tank fed system, you probably have a pump in the airing cupboard. Directly underneath the pump should be a feed (to bring cold water in) and vent (to push air out) pipe. If these two pipes are installed incorrectly you will get air problems. Because it's on the inlet to the pump, its under negative pressure (sucking), so it may suck air instead of sucking water in. Once air is drawn into the system, if the pipework is incorrect, the system will not be able to naturally deal with it. Even if these pipes are correctly installed, blockages in these pipes can upset the balance, and it can mimic being incorrectly installed. One of the most common blockages in heating system is on the cold feed pipe directly underneath the pump. The point where it connects to the heating is normally a bottle neck for debris. We can normally test for blockages by using a magnet on the pipework, if the magnet sticks, the chances are it needs attention. Magnets don't stick to copper, but they stick to the build up of iron oxide inside.

Partially Blocked Heating Pipe |

The best way forward for pipework issues is to have them put right. There are so many installers who carry out a powerflush but leave or ignore the cause of the problem. Suffice to say future problems are imminent.

Symptoms = brown or orange water in radiators, noisy when first turned on, frequent bleeding of radiators required, failing components

Solution = powerflush, pipework alteration, system protection filter, inhibitor

Symptoms of requiring a powerflush |

New installations

When installing a system from new, it is normally suffice to do hot and cold draindowns and refills without a powerflush machine. This should get the flux and installation debris out of a new install. However, when we install a new boiler on an old system, unless we are 100% sure that the system is clean, one should always seriously consider a powerflush. New boilers are particularly susceptible to debris and iron oxide left over from years of build up, and the waterways inside are a lot more delicate. It's not worth the risk, boilers cost a lot of money, and it's vital the water running through the system is clear. Manufacturers nowadays demand that systems are powerflushed, otherwise the warranty will be invalid until the water is proved to be clean.