Vented Cylinders

This is the most common form of cylinder available, and may be connected to a central heating system, with an immersion heater as a backup. It can operate as a stand alone unit with an immersion heater only. (often called direct cylinders). They are normally made from copper, and more recently stainless steel, due to spiralling prices of copper on the commodities market.

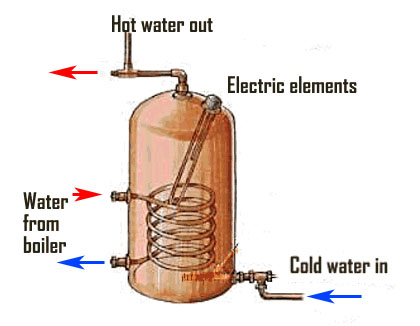

Indirect cylinder takes heat from boiler or immersion heater |

|---|

It is called indirect as there is a large coil inside, which is where the heating water runs through. This is just like an element in a kettle. These are your standard hot water tank/cylinder in you airing cupboard, and normally are 3 ft tall by 18 inches diameter, and some larger ones are 42 inches tall by 18 inches diameter.

|

The vented part in the name comes from the need for a tank in the loft. This tank in the loft helps to push the hot water out of the cylinder via gravity, and replace the water you have just used. The loft tank is also there to provide expansion, as when your water warms up, it expands. So as your cylinder warms up, thus the water level in the loft tank will rise slightly. It is important to set the level of the water correctly from a cold start, if its too high, as soon as the water level rises in the tank, water will go out of the overflow.

Combination Cylinder

We don't always have to have a tank in the loft, where space is limited, such as in flats where we have no loft space, we can install a combination cylinder. This is a standard vented copper cylinder with a small tank braised on top. The whole arrangement is taller than a standard set up, typically 48 inches high, and has to be raised off the floor on a suitable base to get more gravity acting upon the cylinder. This is the main downside, having

Combination Cylinder Combination Cylinder |

|---|

to elevate the tank, and the flow rate is not quite as good at the very highest tap in the house. They are also a lot more expensive than standard cylinders. Combination cylinders were also manufactured as square units. These were mainly fitted in council type properties in the 1980's and 1990's, and are very expensive when they need to be changed.

One interesting addition to the vented cyinder range recently has been high recovery cylinders. The coil inside is a lot smaller in diameter, so there is a lot more in contact with the water. This means heat up times of around 15-20 minutes from cold to a full tank of hot water. This is more than twice as quick as a standard cylinder.

Be Safe

With any stored hot water, you have to be careful with tanks in the loft. Dead insects and even birds have been found in storage tanks, so care must be taken in covering the tank. Remember that stored water kept between 20 and 55 degrees can harbour legionnaires disease causing bacteria. To reduce this, we set our water in the cylinder to come out at 60 degrees C where possible, if that's too hot then at least 55 degrees C

There is now a kit called a 'byelaw 30' kit, which contains a lid, insect mesh for the overflow, bungs for the vent pipe entry point, and also an insualtion jacket. These are an absolute must when installing new tanks in the loft.

Always make sure any tanks in the loft are adequately supported, as there is a potential for scalding water to enter these tanks, and if they overflow or come through the ceiling, they may cause injury.

Power to the Shower

An upgrade to a standard vented cylinder is the addition of a shower booster pump. You can get an invigorating power shower experience with the simple addition of a pump. But please consult your plumber to make sure your cylinder is big enough to cope with the demand!

| Advantages | Disadvantages |

|---|---|

| Cheap and easy to install | Limited by amount of water in tank |

| Backwards compatible with gravity systems | Slow heat up time |

| Good water flow rates | Tanks in loft can get dirt/legionnaires |

| Immersion as a backup | Pipes/Tanks can freeze in loft |