Hot Water Cylinders

There are two methods of obtaining hot water on tap in a domestic property. These are instantaneous, in the form of a combi boiler or water heater, and via a stored hot water solution. Here, we look at the different types of cylinders available, and describe there application, and pros and cons.

Indirect Vented Cylinder

This is the most common form of cylinder available, and may be connected to a central heating system, or as a stand alone unit with an electrical immersion heater. (often called direct cylinders). It is called indirect as there is a large coil inside, which is where the heating water runs through. This is just like an element in a kettle. These are your standard hot water tank/cylinder in you airing cupboard, and normally are 3 ft tall by 18 inches diameter, and some larger ones are 42 inches tall by 18 inches diameter.

|

The vented part in the name comes from the need for a tank in the loft. This tank in the loft helps to push the hot water out of the cylinder via gravity, and replace the water you have just used. The loft tank is also there to provide expansion, as when your water warms up, it expands. So as your cylinder warms up, thus the water level in the loft tank will rise slightly. It is important to set the level of the water correctly from a cold start, if its too high, as soon as the water level rises due to heat, water will go out of the overflow.

Advantages; Cheap, Easy to Install, can be used on old systems such as gravity hot water, normally high flow rates of water, can have a backup with immersion heater

Disadvantages; Limited by amount of water in tank, can be slow warm up time, takes up space, tanks in loft can get dirt in them if uncovered, which means dirt in hot water! Pipes can freeze in loft!

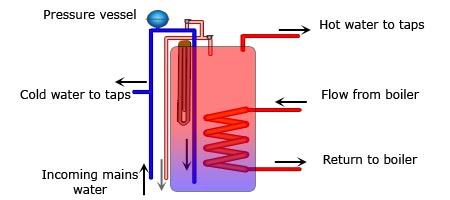

Unvented Hot Water Cylinder

These are the ultimate in hot water delivery. A large tank, with water inside stored under pressure. They are well insulated, heat up rather quickly and can give you a tremendous power shower experience! Cold water is pushed into the tank at the base, and this forces the hot water out of the top under pressure. They can be connected to your heating system, or as a standalone with immersion heaters. If connected to the heating system the immersion can act as a backup. There are no tanks in the loft, but there may be a separate vessel to install above the cylinder.

Unvented Cylinder Principle |

Working on and installing unvented cylinders requires a separate qualification, as there are some very important safety considerations when storing hot water under pressure. You may also need to notify building control at your local council when installing an unvented cylinder. If you choose this option, as always please make sure the installer carries the relevant qualification

Advantages; the ultimate mains pressure hot water, no tanks required, can be located anywhere even in the loft, can be very energy efficient, most modern units come with a 25 year guarantee

Disadvantages; Very heavy - consideration must be taken when installed in lofts as they can weigh 200kg when full, large in size,additional safety controls and overflow required, may require larger cold main to work properly, more expensive

Thermal Stores

These are mainly a british concept, and come in two forms, direct and indirect. The direct thermal stores work on the idea of keeping a tank of water hot full of central heating water, and then passing a coil through it with cold water, which comes out hot the other end. These tend to suffer with water problems such as sludge and oxidisation. They are also more expensive to run than standard cylinders, you are in effect running two central heating systems as you heat up at least 120 litres of water in the tank, turn on the heating, this water goes round the radiators, and is then re-heated again.They are a hybrid of standard cylinder because they are vented (open to atmosphere), but they give you mains pressure hot water.

Gledhill Torrent Thermal Store |

We also have indirect thermal stores, with two coils inside, one to heat the bulk of the water, and one for the hot water delivery. These are much better than direct, as any work on the system does not require you to drain the whole cylinder down. You can also powerflush these systems, whereas with direct you are hindered by their design. You need an extra tank for these, one for the tank, and one for the heating as standard. You can have an immersion heater for thermal stores, as a backup or as a main heat source instead of connecting it to the heating system.